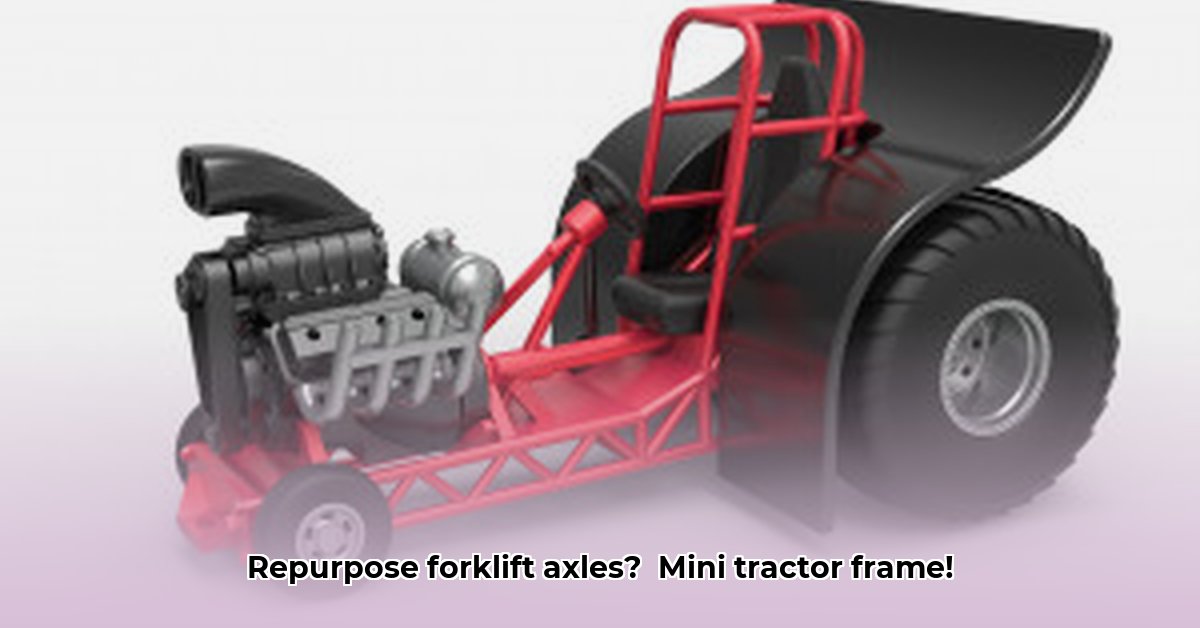

Building a competitive mini-rod pulling tractor can be expensive. This guide demonstrates a cost-effective and environmentally friendly approach: repurposing used forklift axles. This method combines practicality with sustainability, offering significant advantages for both budget-conscious competitors and environmentally conscious engineers. For more information on suitable hydraulic fluids, check out this resource.

Why Use Forklift Axles?

Using forklift axles for your mini-rod pulling tractor offers several key benefits:

Cost Savings: Repurposed forklift axles are significantly cheaper than new, custom-made axles, freeing up your budget for other crucial components or upgrades. This can be a game-changer for smaller teams or individual builders. Isn't maximizing your budget a priority?

Suitable Gear Ratios: Forklift axles often have gear ratios well-suited to the high-torque demands of mini-rod pulling, maximizing power transfer and potentially minimizing slippage. This directly impacts performance on the track. Could a better power transfer mean a faster run?

Compact Design: The relatively compact width of many forklift axles can contribute to improved maneuverability and stability, providing a competitive edge on the track. How important is nimble handling in intense competition?

Proven Durability (with caveats): Forklift axles are designed for heavy-duty applications, suggesting inherent strength and durability. However, careful inspection and potential reinforcement are crucial given the unique stresses of mini-rod pulling.

Step-by-Step Adaptation Guide

This section provides a detailed, actionable guide to adapting a forklift axle for your mini-rod pulling tractor. Each step emphasizes safety and robust construction.

1. Axle Selection and Assessment (Critical First Step): Begin by meticulously inspecting potential forklift axles for cracks, bends, or excessive wear. Measure the axle’s dimensions (length, diameter, width) and determine the gear ratio. Choose an axle with sufficient load capacity and a gear ratio suited to your tractor's engine and intended pulling style. Don't rush this stage—the right axle is fundamental.

2. Modification and Preparation (Precision Required): This step may involve machining or welding to adapt the axle to the tractor's frame. You may need to create custom brackets or modify existing mounting points. Precise measurements are paramount to ensure proper fit and alignment. If welding is required, ensure you have the necessary skills or seek professional help.

3. Mounting the Axle (Secure Foundation): Securely fasten the modified axle to the tractor frame using high-strength welds and appropriate fasteners. Precise alignment is vital; misalignment can lead to premature wear or catastrophic failure. Over-engineering this stage is recommended.

4. Connecting the Drive System (Efficient Power Transfer): Connect the axle to the tractor's power source using appropriately sized and rated drive shafts and components. Pay close attention to alignment to prevent vibration and maximize power transfer. A poorly connected drive system severely impacts performance.

5. Testing and Troubleshooting (Real-World Evaluation): Before intense use, conduct thorough testing to identify potential weaknesses or issues. Stress testing beyond expected loads is advisable. Address any problems revealed during testing and reinforce any potential weak points.

6. Safety Precautions (Paramount): Always wear appropriate safety gear (gloves, eye protection, etc.) during the entire process. Regular inspections of the axle and mounting system are critical for long-term safety and performance.

Durability, Sustainability, and the Long Game

Repurposing forklift axles offers significant sustainability advantages. However, it's crucial to address potential durability concerns. Forklift axles, while robust, might not be as durable as custom-designed components for mini-rod pulling.

Mitigation Strategies: Regular inspections, stress testing before competition, and reinforcement of critical areas can significantly extend the axle's lifespan.

Quantifiable Sustainability: Using repurposed parts drastically reduces the demand for new materials, resulting in lower manufacturing costs, reduced energy usage, and decreased waste. While precise quantifications require further research (future research should focus on generating LCA data), the environmental advantages are clear.

Regulatory Compliance

Before operating your modified tractor, ensure it complies with all local and national safety and environmental regulations. Consult with relevant authorities to avoid legal issues and ensure safe operation.

Conclusion

Repurposing forklift axles provides a cost-effective and sustainable pathway to building high-performance mini-rod pulling tractors. By following this guide, prioritizing safety, and understanding the inherent limitations, competitors and engineers can create powerful, environmentally conscious machines. However, continued research into the durability and long-term sustainability of this approach is crucial.